I3CMOS05000KMC Industrial Camera/Analytical Imaging

Product Introduction

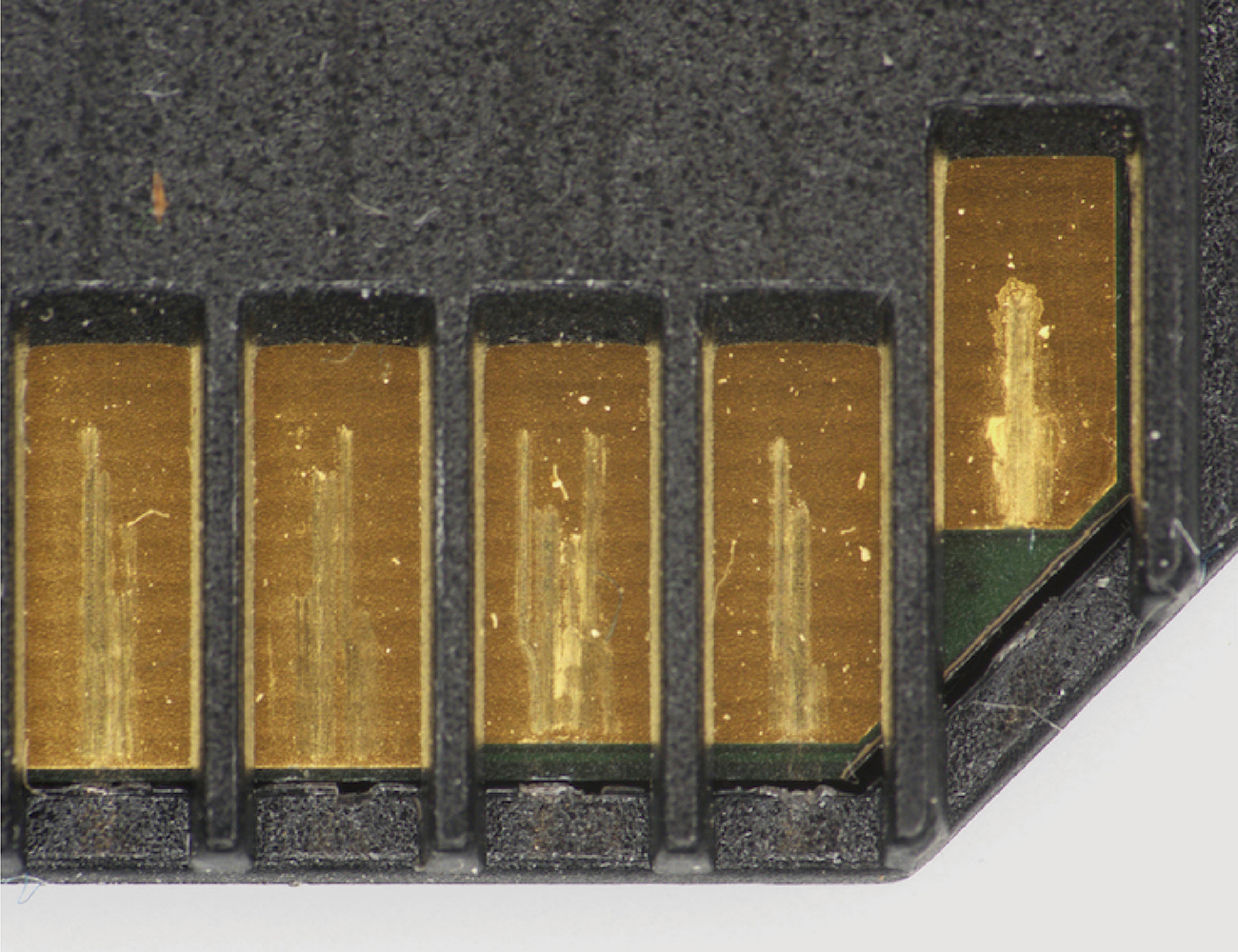

IMX250MZR Polarsens polarization monochrome camera, 5 MP global shutter; typical frame rates: 35.6/87.6 fps (resolution-dependent). USB3.0, C-mount, 8/12-bit; format 2/3". Built-in micro-polarization array, suitable for scratch/stress/reflective surface detection.

Key Features

- Sensor: Sony IMX250MZR (Polarsens); pixel: 3.45 µm

- Resolution/format: 5.0 MP; 2/3" (11.06 mm)

- Polarization capability: Four-direction polarization pixel array, suitable for reflection/stress analysis

- Shutter/frame rate: Global shutter; 35.6 fps/87.6 fps

- Bit depth/dynamic: 8/12-bit; 73.6 dB

- Interface/mount: USB3.0/C-mount; power: USB3.0

- I/O: Opto-isolated input/output + GPIO

- Image functions: Hardware ISP, ROI/mirroring; polarization processing (software-dependent)

- Dimensions/weight: 33×33×33 mm; 70 g

- Certification: CE/FCC

Product Details

| Key Parameters | |

| Model | I3CMOS05000KMC |

| Sensor | Sony IMX250MZR (Polarsens) |

| Effective Pixels / Resolution | 5.0 MP (2448×2048) |

| Frame Rate (Full Resolution) | 35.6 fps @ 2448×2048; 87.6 fps @ 1224×1024 |

| Shutter Type | Global Shutter |

| Color Type | Monochrome (Polarization) |

| Imaging Performance | |

| Pixel Size | 3.45 µm × 3.45 µm |

| Sensor Size | 8.45 mm × 7.07 mm |

| Diagonal | 2/3" (11.02 mm) |

| Dynamic Range | 73.6 dB |

| Bit Depth | 8/12-bit |

| Sensitivity | 684 mV |

| Interface & Mechanical | |

| Data Interface | USB3.0 |

| GPIO | 1 opto-isolated input, 1 opto-isolated output, 1 non-isolated I/O port |

| Lens Mount | C-mount |

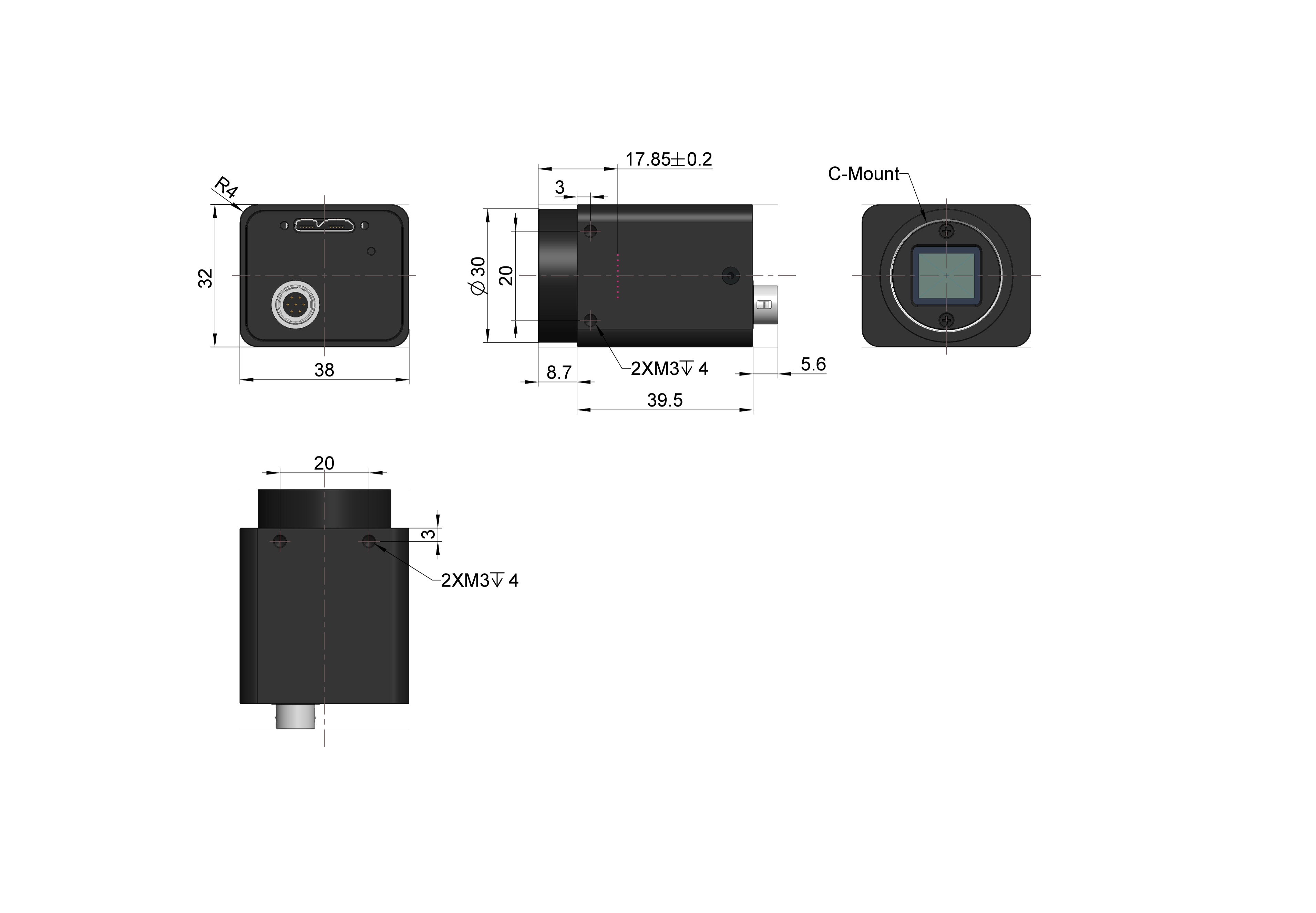

| Dimensions | 33 mm × 33 mm × 33 mm |

| Weight | 70 g |

| Power Supply | USB3.0 interface powered |

| Environment & Certification | |

| Operating Temperature / Humidity | -10 °C to +50 °C / 20% to 80% (non-condensing) |

| Storage Temperature / Humidity | -30 °C to +70 °C / TBD |

| Operating System | Windows/Linux/macOS/Android multi-platform SDK (native C/C++, C#/VB.NET, Python, Java, DirectShow, Twain, etc.) |

| Certification | CE/FCC |

Product Overview

The I3CMOS05000KMC represents a precision-engineered industrial camera solution designed specifically for demanding machine vision applications. Featuring a Sony IMX250MZR (Polarsens) high-performance image sensor, this platform delivers exceptional capabilities for automated inspection and quality control environments requiring precise timing and compact integration.

Industrial Performance Characteristics

The I3CMOS Series establishes new standards for industrial imaging through its optimized sensor architecture and compact mechanical design. The 5.0 MP (2448×2048) resolution capability combined with 3.45 µm × 3.45 µm pixel pitch delivers exceptional detail resolution across a 8.45 mm × 7.07 mm sensor format, ensuring consistent performance in automated manufacturing environments.

The implementation of Global Shutter technology eliminates motion artifacts that compromise measurement accuracy in high-speed applications. This design approach ensures temporal precision essential for machine vision systems monitoring rapid manufacturing processes or conducting automated quality inspections where object movement cannot introduce imaging distortions.

High-Speed Data Management

The USB3.0 interface architecture enables maximum frame rates reaching 35.6 fps @ 2448×2048; 87.6 fps @ 1224×1024 , supporting real-time image acquisition and immediate processing feedback required in automated inspection systems. This connectivity standard ensures consistent data throughput without bottlenecks that could compromise production line efficiency.

Advanced image processing capabilities include 8/12-bit color depth processing with dynamic range specifications exceeding 73.6 dB . These parameters ensure accurate color reproduction and contrast resolution necessary for defect detection and quality assessment applications across diverse industrial materials and lighting conditions.

Optical Integration and Sensitivity

Optimized sensitivity specifications of 684 mV enable reliable performance across varying illumination conditions typical in industrial environments. This capability ensures consistent imaging quality whether deployed in controlled inspection stations or variable production environments where lighting conditions may fluctuate.

The standard C-mount interface provides universal compatibility with industrial lens systems, while optional 0.5×/0.63×/1× relay adapters enable integration with specialized optical configurations. This flexibility supports diverse application requirements from macro inspection to precision microscopic analysis.

Compact Integration Design

The exceptionally compact form factor measuring 33 mm × 33 mm × 33 mm with a total system weight of 70 g addresses space constraints inherent in automated manufacturing systems. The USB3.0 interface powered power architecture eliminates additional power supply requirements, simplifying installation and reducing system complexity.

Professional software integration supports comprehensive development environments including C/C++, C#, Python, DirectShow, GenICam platforms across Windows/Linux/macOS/Android multi-platform SDK (native C/C++, C#/VB.NET, Python, Java, DirectShow, Twain, etc.) operating systems. This compatibility ensures seamless integration with existing automation infrastructure and enables custom application development tailored to specific manufacturing requirements.

Core Performance Metrics

Resolution

5.0 MP (2448×2048)

Frame Rate

Up to 35.6 fps @ 2448×2048; 87.6 fps @ 1224×1024

Pixel Size

3.45 µm × 3.45 µm

Data Interface

USB3.0

Industrial Application Capabilities

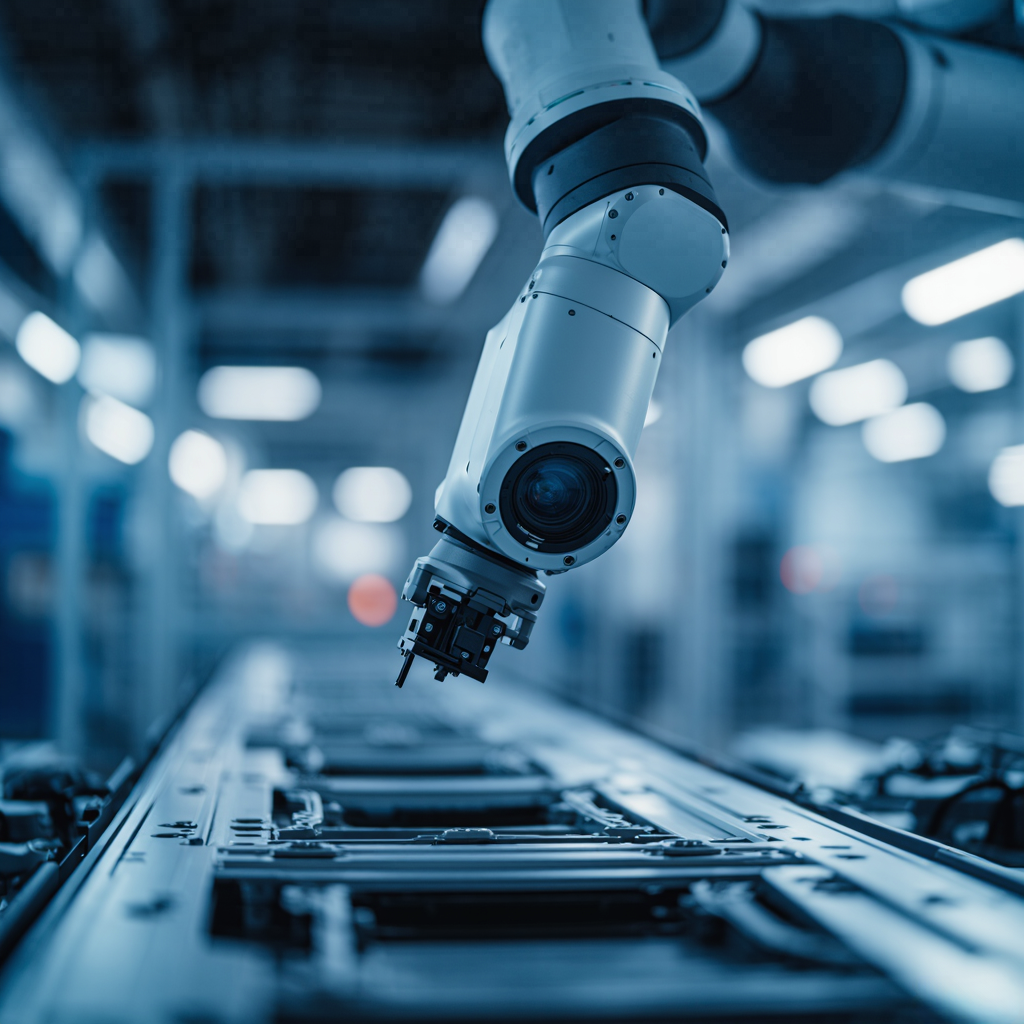

Manufacturing Integration

Engineered for demanding production environments including automated assembly lines, quality control stations, and precision manufacturing systems requiring consistent imaging performance and reliable operation

High-Speed Precision

Global shutter architecture eliminates motion blur and temporal distortions, ensuring accurate measurement and inspection results in high-speed manufacturing processes and dynamic object tracking applications

Space-Efficient Design

Ultra-compact mechanical design addresses space constraints in automated systems while maintaining professional-grade imaging performance and reliable operation in challenging industrial environments

System Integration

Comprehensive software development kit enables seamless integration with existing automation infrastructure, supporting custom application development and specialized machine vision algorithms

Industrial Excellence

The I3CMOS05000KMC industrial camera delivers exceptional value through its precision engineering, compact design, and comprehensive integration capabilities. This platform represents the optimal solution for demanding manufacturing environments requiring reliable high-speed imaging, precise timing, and seamless automation system integration.

I3CMOS05000KMC Technical Documentation

Comprehensive PDF documentation including detailed technical specifications and mechanical drawings

SDK Development Kit

Multi-platform support for Windows, Linux, macOS and comprehensive API documentation

3D CAD Models

Precision STEP format files for mechanical design integration and system planning

Package Contents · I3CMOS05000KMC #

Standard package contents for I3 series industrial machine vision cameras (USB3 / GigE / 10GigE)

Recommended bundle (USB3)

- Camera body - USB3.0 interface

- I/O cable - 6-pin cable or extension cable

- Cable - Micro USB3.0 cable

- Lens (optional)

Product Dimensions · I3CMOS05000KMC #

Dimensions overview for I3 series industrial machine vision cameras

The I3CMOS series from ToupTek offers high-performance USB3.0 industrial cameras spanning 2–20.4 MP, built with premium Sony and Gpixel CMOS sensors and supporting 1/1.7" to 1.1" formats. The series features global shutter capture with high speed, low noise, and wide dynamic range, making it ideal for industrial inspection, machine vision, and research imaging.

Key Features

Global shutter technology

Eliminates motion blur for precise capture

Premium sensors

Sony/Gpixel CMOS sensors

High-speed imaging

Up to 132 fps capture

Wide dynamic range

70 dB+ dynamic range performance

Performance Highlights

Resolution range

2–20.4 MP

Multiple optionsMax frame rate

132 fps

@ 2 MPDynamic range

70.8 dB

High-contrast scenesCompact size

38×38×33

mm bodyIn-depth Product Overview

High-performance sensor platform

Equipped with Sony IMX430, IMX421, IMX541, and Gpixel GMAX sensors, the lineup covers diverse pixel sizes and resolutions. Pixel sizes range from 2.74 µm to 4.5 µm, balancing fine detail with low-light sensitivity. These high-end sensors deliver excellent image quality under varied lighting, with dark current as low as 0.15 mV, ideal for long-exposure use.

Global shutter high-speed imaging

The entire series supports global shutter technology for high-speed dynamic scenes, effectively eliminating motion blur. Typical 2 MP models reach up to 132 fps, while 20.4 MP variants still deliver 17.5 fps at full 4496×4496 resolution. This speed makes the cameras excel in high-speed production line inspection and motion analysis.

Flexible imaging control

Offers 1×1, 2×2, 3×3, and 4×4 hardware and software binning so users can balance speed, sensitivity, and image quality. Supports 8-bit/12-bit output to meet precision requirements. Some models reach dynamic range above 70 dB with SNR around 40 dB, preserving rich detail in high-contrast scenes.

Compact, reliable industrial design

Built with a compact 38×38×33 mm full-metal design, weighing about 70 g and consuming under 3 W. USB3.0 (USB3.1 GEN1) single-cable power simplifies integration. Opto-isolated I/O eases embedding into automation systems. Operating temperature is -10 to 50 °C with 20%–80% humidity (non-condensing) for stable long-term industrial use.

Comprehensive software ecosystem

Compatible with ToupView software and Windows, Linux, macOS, and Android. The SDK provides C/C++, C#/VB.NET, Python, DirectShow, and Twain interfaces for easy secondary development. Rich SDK features and standardized I/O enable rapid integration into machine vision or research systems, shortening development cycles.

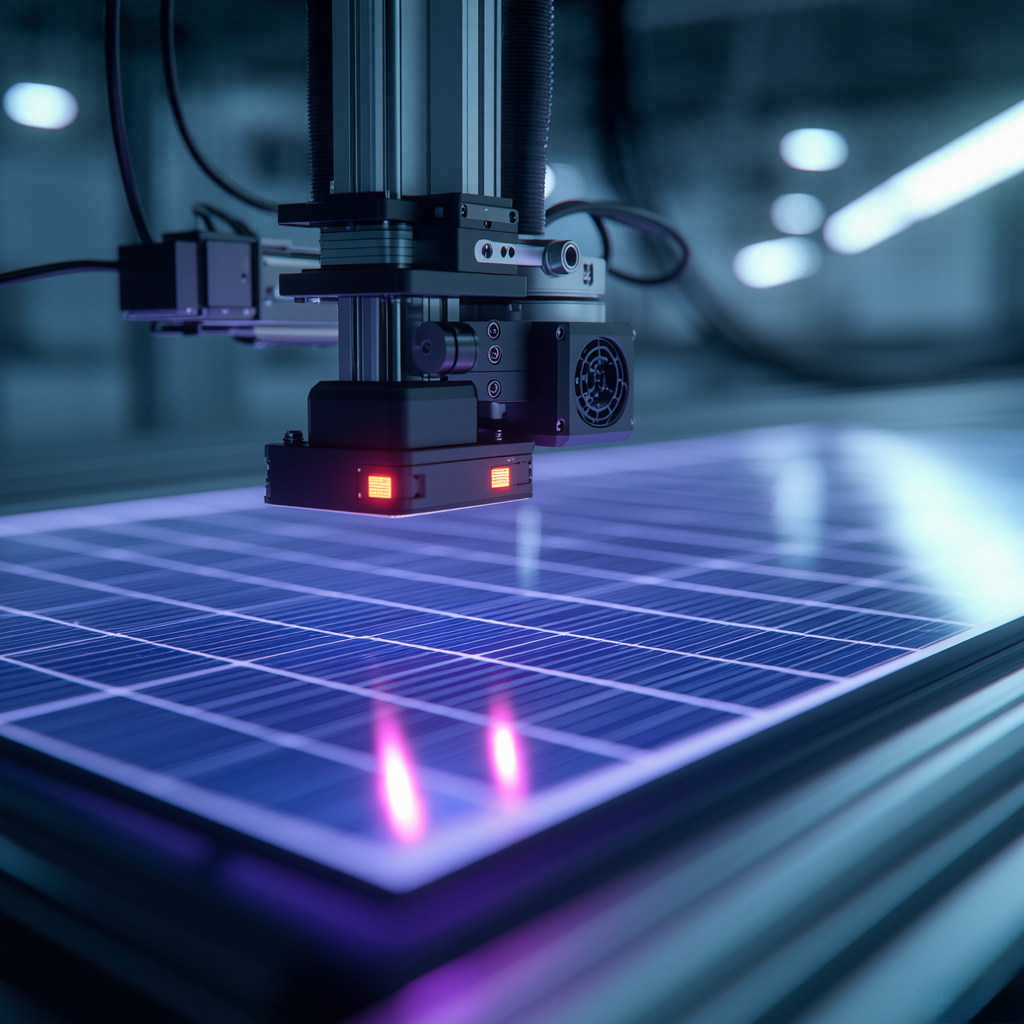

Applications

I3CMOS series application examples across industrial imaging

I3CMOS Series Key Advantages

Global shutter

Ghost-free imaging

High-speed capture

132 fps

Wide dynamic range

70.8 dB

Low noise

0.15 mV

Premium sensors

Sony/Gpixel

Multi-level binning

4 modes

Compact design

38×38×33 mm

Low power

<3 W