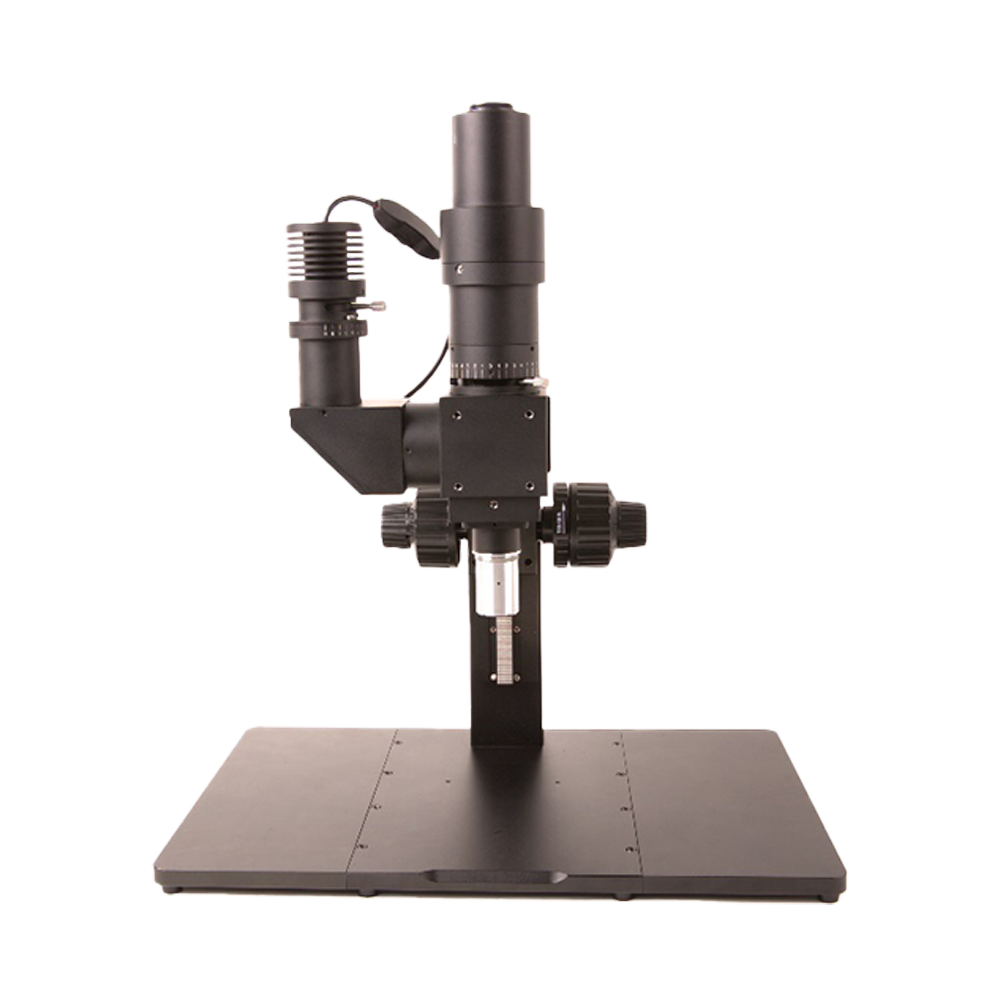

PLM100 Series Polarised Light Microscope System

Product Introduction

A polarising microscope is designed to study anisotropic transparent or opaque materials. Substances exhibiting birefringence can be clearly distinguished under a polarising microscope—often without staining. Reflected polarising microscopes are indispensable for analysing birefringent materials using the polarisation characteristics of light.

Product Features

- Standard and long working distance objectives available

- Imaging path: 1X (tube lens focal length 200 mm) with optional reducers

- Image circle: 25 mm

- Spectral range: visible light

- Camera interfaces: C / M42 / M52 (optional)

- Illumination: critical illumination or Köhler illumination (optional)

- Light source: 10 W white LED / blue LED (optional)

System Configuration and Parameters

Professional polarized light microscope system providing precise solutions for anisotropic material analysis

System working principle

PLM100 utilises the polarisation properties of light. A polariser and analyser work together to examine materials exhibiting birefringence.

Polariser

Converts natural light into linearly polarised light for illuminating the specimen.

Sample interaction

Birefringent materials split the polarised beam into two orthogonal components travelling at different speeds, producing an optical path difference.

Analyser

Placed orthogonally to the polariser, it analyses the polarised state after the specimen, generating interference patterns.

Imaging system

Magnifies and relays the interference image to the camera or eyepiece, revealing anisotropy and stress distribution.

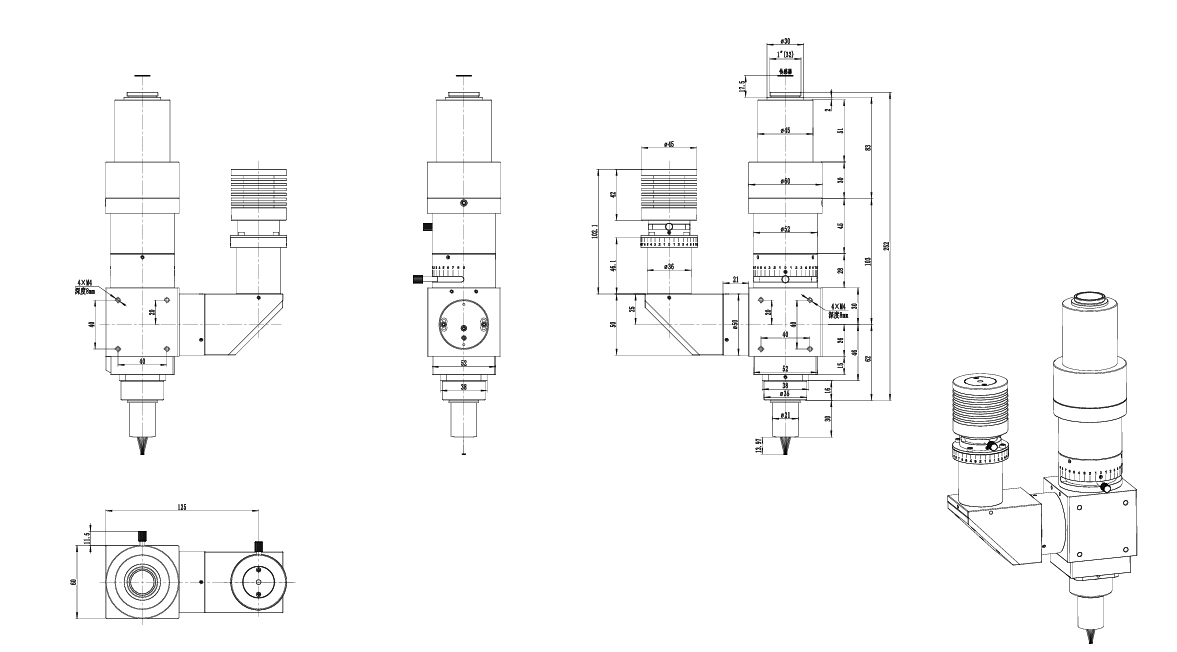

Objective Series Parameters

Standard working-distance objective series (60 mm parfocal distance with a 200 mm tube lens )

| Model | Magnification | Numerical Aperture (NA) | Working Distance | Focal Length | Resolution | Object Field | Image Field |

|---|---|---|---|---|---|---|---|

| DIC5XA | 5X | 0.15 | 23.5mm | 39mm | 2.2µm | 5mm | 25 mm |

| DIC10XA | 10X | 0.3 | 22.8mm | 20 mm | 1.1µm | 2.5mm | 25 mm |

| DIC20XA | 20X | 0.4 | 19.2mm | 10 mm | 0.8µm | 1.1mm | 25 mm |

| DIC50XA | 50X | 0.55 | 11mm | 4 mm | 0.6µm | 0.44mm | 25 mm |

Long working-distance objective series (95 mm parfocal distance with a 200 mm tube lens )

| Model | Magnification | Numerical Aperture (NA) | Working Distance | Focal Length | Resolution | Object Field | Image Field |

|---|---|---|---|---|---|---|---|

| DICL2XA | 2X | 0.055 | 33.7mm | 95 mm | 6.1µm | 12.5mm | 25 mm |

| DICL5XA | 5X | 0.14 | 33.6mm | 40 mm | 2.2µm | 5mm | 25 mm |

| DICL10XA | 10X | 0.28 | 33.4mm | 20 mm | 1.2µm | 2.5mm | 25 mm |

| DICL20XA | 20X | 0.34 | 29.5mm | 10 mm | 0.8µm | 1.25mm | 25 mm |

| DICL50XA | 50X | 0.5 | 18.9mm | 4 mm | 0.7µm | 0.5mm | 25 mm |

System Technical Specifications

Optical System

- Imaging Path

- 1X (tube lens focal length 200 mm), custom reduction optics available

- Image Size

- 25 mm

- Spectral Range

- Visible light

- Tube Lens Focal

- 200 mm

Illumination System

- Illumination Type

- Selectable critical or Köhler illumination

- Light Source

- 10W LED

- Light Options

- Optional white or blue LED

Polarization System

- Camera Interface

- Selectable interfaces: C / M42 / M52

- Objective Thread

- M26×0.705

- Polarization Config

- Polarizer + Analyzer (90° orthogonal)

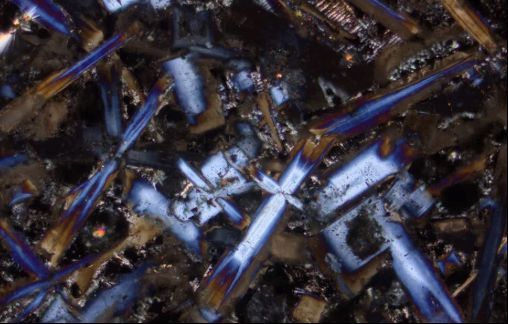

Typical Application Cases

Professional applications of PLM100 system across various fields

Geology, Petrology, and Mineral Analysis

PLM100 is central to geological studies, enabling precise analysis of mineral crystal structures and compositions. It is particularly suited to metal ores (oxides, sulphides, silicates), asbestos fibre detection, and coal petrography.

- Accurate identification of minerals and crystal structures

- Characterisation of ore composition

- Quantitative asbestos fibre detection

- Coal component analysis

- Measurement of crystal optical properties

Stress Birefringence in Materials

The system detects stress distribution in glass, plastics, and polymers via photoelastic effects, visualising internal stress patterns for quality control and failure analysis.

- Non-destructive stress testing

- Visual stress maps

- Identification of stress concentration zones

- Evaluation of glass inclusions

- Quality control for injection-moulded plastics

Specific Application Cases

- Residual stress assessment in glass products

- Edge stress analysis in plastic housings

- Uniformity evaluation of polymer films

- Defect detection in composites

More Application Fields

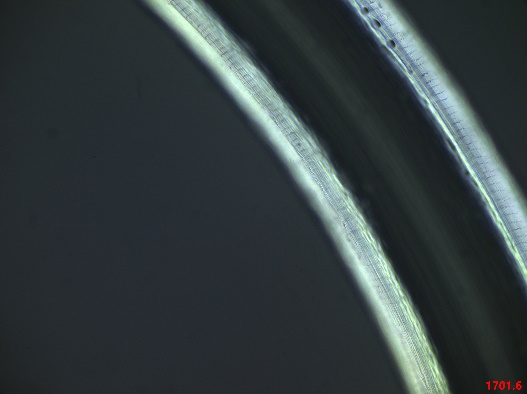

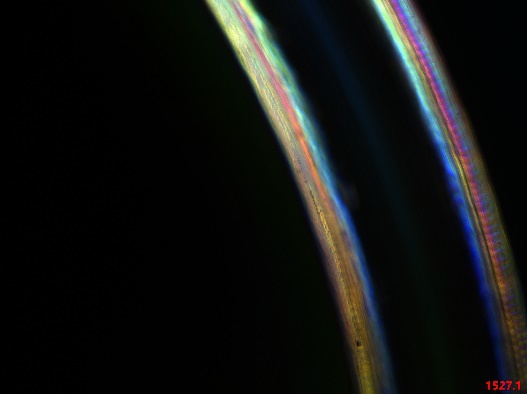

Textile and Fibre Testing

PLM100 is valuable for textile industry quality control, distinguishing fibre types, evaluating fibre orientation, and analysing fabric structures for composition studies and quality assessment.

- Differentiation of natural and synthetic fibres

- Quantitative fibre orientation analysis

- Fabric structure characterisation

Comparison with other microscopy techniques

| Comparison Technique | PLM100 System Advantages |

|---|---|

| Brightfield microscopy | PLM visualises birefringence and anisotropy that brightfield systems cannot reveal. |

| DIC microscopy | PLM provides polarisation-based contrast, ideal for mineral and stress analysis, whereas DIC emphasises relief-like contrast in transparent specimens. |

| Fluorescence microscopy | PLM does not require fluorescent labelling and excels at analysing crystalline structures and stress patterns in transparent materials. |

System Configuration and Accessories

Standard Configuration

- PLM100 main system

- Polariser and analyser modules

- Retardation plate set

- Coaxial polarised illumination module

- Precision focusing stage

Optional Accessories

- Standard and long working distance objective sets

- Rotating specimen stage

- Automated stage control

- Image acquisition and analysis software

- Custom-wavelength LED sources

- Anti-vibration platform

- Compensator kit

- Rotary specimen stage

The PLM100 series features a modular design that can be flexibly configured according to specific analysis requirements

PLM100 System Advantages

Professional polarized light microscopy technology revealing material anisotropic characteristics

Crystal Structure Analysis

Accurately identify mineral crystal types, analyze crystal optical properties, providing reliable data for geological research.

Stress Birefringence Detection

Non-destructive detection of internal stress distribution in materials, achieving stress visualization through photoelastic effects.

Fiber Material Identification

Accurately identify natural and synthetic fibers, assess fiber orientation, supporting textile quality control.

High Extinction Ratio Design

Professional polarizing objectives eliminate internal stress interference, ensuring polarized imaging quality and measurement accuracy.

No Sample Treatment Required

Directly observe material intrinsic optical properties without staining or special preparation, maintaining sample original state.

Quantitative Analysis Capability

Combined with compensators for optical path difference measurements, enabling quantitative analysis of material thickness and birefringence.