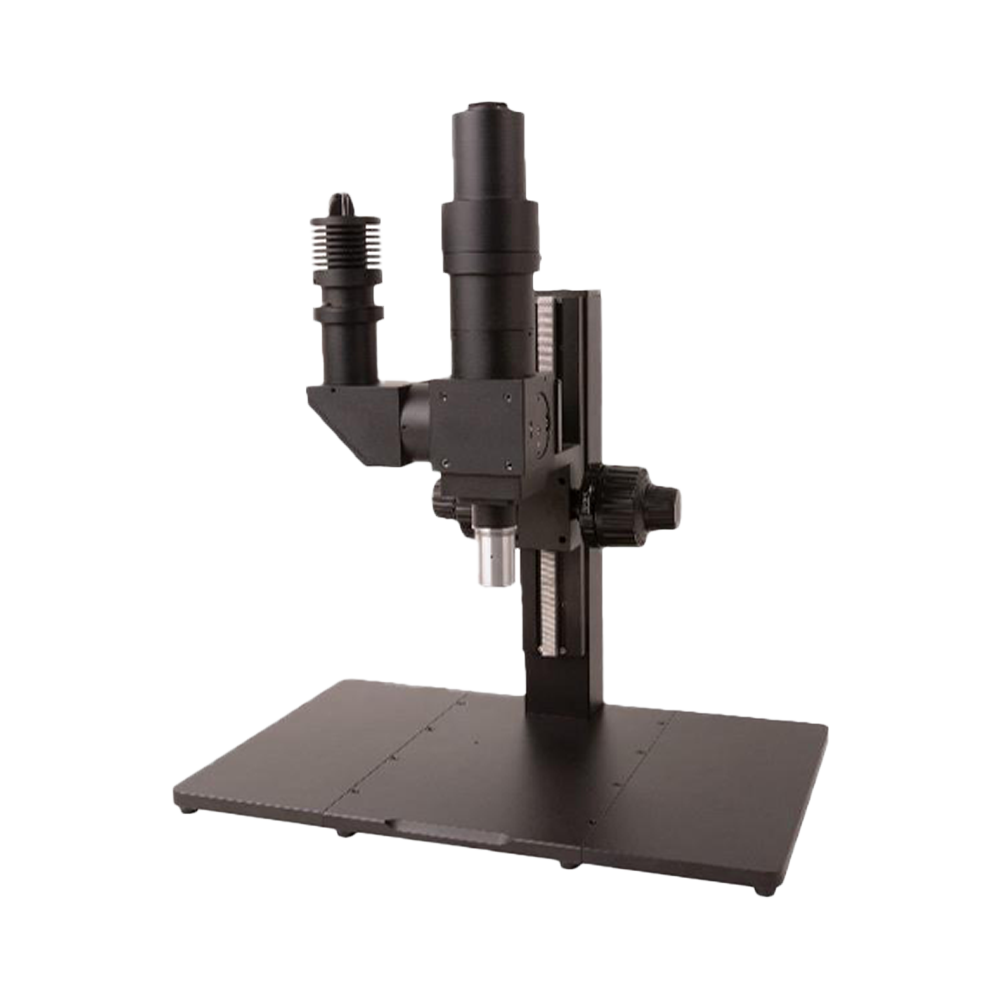

BMM100 Series Brightfield Metallographic Microscope System

Product Introduction

A brightfield metallographic microscope is a precision optical instrument composed of illumination, imaging, and mechanical subsystems. It is widely applied across modern science and technology and serves as a critical inspection tool. Metallographic microscopes play an increasingly important role in biology, geology, mining, medicine, and related disciplines.

Product Features

- Integrated precision design for illumination, imaging, and mechanical subsystems

- Standard working distance objective series (60 mm parfocal distance)

- Long working distance objective series (95 mm parfocal distance)

- Selectable critical illumination or Köhler illumination

- 10 W high-brightness LED illumination system

- 25 mm large image circle design

- Multiple camera interface options (C / M42 / M52)

- Selectable white LED or blue LED light sources

System Configuration and Parameters

Professional brightfield metallographic microscopy system providing precise imaging solutions for material inspection

System working principle

The BMM100 brightfield metallographic system uses reflected brightfield illumination and precision optical design to deliver high-quality imaging of material microstructures.

Illumination system

Provides uniform, stable epi-illumination with selectable critical or Köhler modes to ensure optimal surface lighting.

Imaging system

Employs high-quality optics and an optimised light path with dedicated objectives for high-resolution, high-contrast imaging.

Mechanical system

Precision mechanics guarantee system stability and repeatable positioning accuracy, supporting long-duration observation and inspection.

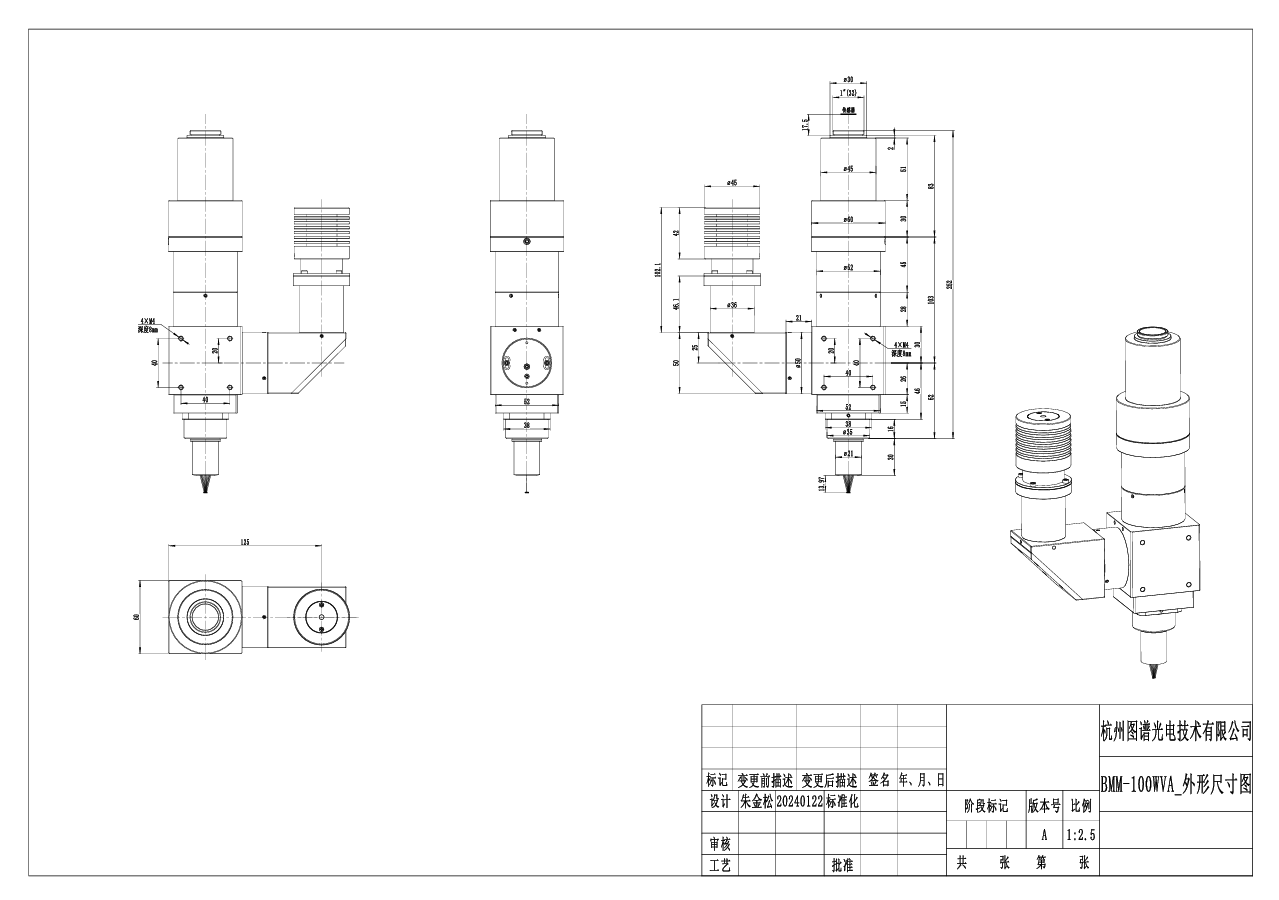

Objective Series Parameters

Standard working-distance objective series (60 mm parfocal distance with a 200 mm tube lens )

| Model | Magnification | NA | Working Distance | Focal Length | Resolution | Object Field | Image Field |

|---|---|---|---|---|---|---|---|

| BF5XA | 5X | 0.15 | 23.5mm | 39 mm | 2.2µm | 5mm | 25 mm |

| BF10XA | 10X | 0.3 | 22.8mm | 20mm | 1.1µm | 2.5mm | 25 mm |

| BF20XA | 20X | 0.4 | 19.2mm | 10mm | 0.8µm | 1.1mm | 25 mm |

| BF50XA | 50X | 0.55 | 11mm | 4mm | 0.6µm | 0.44mm | 25 mm |

Long working-distance objective series (95 mm parfocal distance with a 200 mm tube lens )

| Model | Magnification | NA | Working Distance | Focal Length | Resolution | Object Field | Image Field |

|---|---|---|---|---|---|---|---|

| BFL2XA | 2X | 0.055 | 33.7mm | 100 mm | 6.1µm | 12.5mm | 25 mm |

| BFL5XA | 5X | 0.14 | 33.6mm | 40 mm | 2.2µm | 5mm | 25 mm |

| BFL10XA | 10X | 0.28 | 33.4mm | 20 mm | 1.2µm | 2.5mm | 25 mm |

| BFL20XA | 20X | 0.34 | 29.5mm | 10 mm | 0.8µm | 1.25mm | 25 mm |

| BFL50XA | 50X | 0.5 | 18.9mm | 4 mm | 0.7µm | 0.5mm | 25 mm |

System Technical Specifications

Optical System

- Imaging Path

- 1X (tube lens focal length 180 mm), custom reduction optics available

- Image Size

- 25 mm

- Spectral Range

- Visible light

- Tube Lens Focal

- 200 mm

Illumination System

- Illumination

- Selectable critical or Köhler illumination

- Light Source

- 10W LED

- Light Options

- Optional white or blue LED

Mechanical System

- Camera Interface

- Selectable interfaces: C / M42 / M52

- Objective Thread

- M26×0.705

- Focusing

- Precision focusing system

Typical Application Cases

Professional applications of BMM100 system in various fields

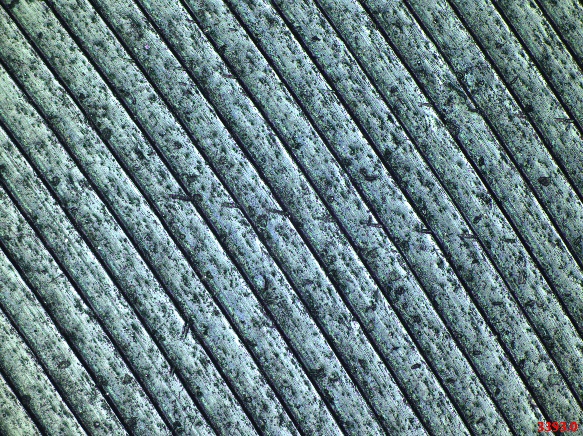

Metal and Alloy Inspection

The BMM100 series is vital for analysing the microstructure of metal and alloy materials, clearly revealing grains, phases, inclusions, and defects to support material performance evaluation and quality control.

- High-resolution observation of metal grain structures

- Accurate identification of phases and inclusions

- Clear visualisation of surface defects

- Supports quantitative metallographic analysis

- Applicable to a wide range of metals and alloys

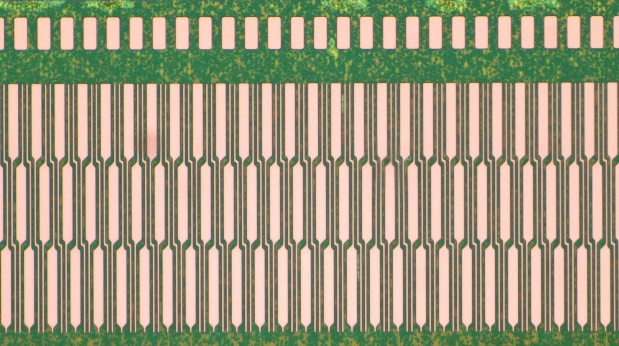

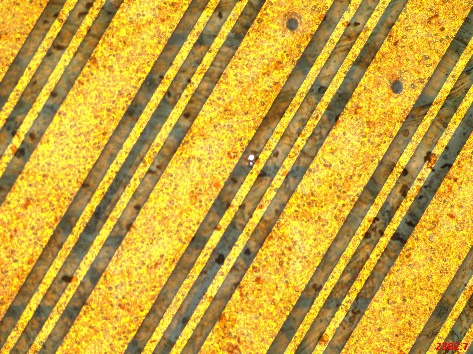

LCD Inspection

The system evaluates pixel structures, flex connections, conductive particle distribution, and other key quality indicators during LCD production to ensure display performance and reliability.

- Clear observation of LCD pixel structures

- Precise inspection of flex interconnect quality

- Assessment of conductive particle distribution uniformity

- Identification of display defects and anomalies

- Supports integration with automated inspection

More Application Fields

Non-Metal Materials Testing

The BMM100 series also applies to plastics, ceramics, and composites, capturing surface morphology and internal structure to support material R&D and quality assurance.

- Observe surface textures on plastics

- Inspect fibre distribution in composites

- Analyse ceramic grain structures

Geological and Mineral Analysis

BMM100 is used for mineral identification, rock structure analysis, and ore grade evaluation, supporting geological exploration and mining development.

- Accurate identification of mineral composition

- Analysis of rock microstructures

- Ore grade evaluation

Biomedical Research

In biomedical applications, the system enables tissue section inspection, cell morphology analysis, and pathology studies, providing precise microscopic imagery for research and clinical diagnostics.

- High-clarity imaging of tissue sections

- Accurate cell morphology observation

- Supports pathological diagnosis

Advantages compared with other microscopy techniques

| Comparison Technology | BMM100 System Advantages |

|---|---|

| Darkfield microscope | BMM100 brightfield imaging delivers truer colour reproduction and higher contrast, making it suitable for most routine material inspections. |

| Polarising microscope | BMM100 is easier to operate, requires no specialised sample preparation, and covers a broader range of applications. |

| Fluorescence microscopy | BMM100 avoids fluorescence labelling, observes intrinsic material characteristics directly, and reduces cost. |

| Electron microscope | BMM100 operates without vacuum conditions, is easier to use, supports live samples, and has lower maintenance costs. |

System Configuration and Accessories

Standard Configuration

- BMM100 main system

- Coaxial polarised illumination module

- Precision focusing mechanism

- Precision focusing stage

- Anti-vibration base

Optional Accessories

- Standard working distance objectives (5X-50X)

- Rotating specimen stage

- Automated stage control

- Reducer optics (0.5X / 0.63X / 0.75X)

- Custom-wavelength LED sources

- Anti-vibration platform

- Sample holding fixtures

- Dust cover

The BMM100 Series features modular design, allowing flexible configuration based on specific inspection requirements

BMM100 System Advantages

Professional brightfield metallographic microscopy technology providing precise material inspection solutions

High-Precision Imaging System

Optimized optical design and high-quality optical elements ensure clear and sharp images with authentic color reproduction.

Wide Application Range

Suitable for inspection of metals, alloys, plastics, ceramics, and various other materials, meeting quality control requirements across industries.

Modular Design

Flexible configuration options allow selection of objectives, illumination methods, and camera interfaces according to requirements, facilitating upgrades and maintenance.

LED Cold Light Source

10 W high-power LED illumination with low heat generation and long service life, providing stable and uniform lighting effects.

Stable Mechanical Structure

Precision focusing mechanism and anti-vibration design ensure long-term precision and image stability.

Easy Operation

No special sample preparation required, intuitive operating interface for quick mastery, improving inspection efficiency.