Introduction

BSM SWIR Modular Microscope System

The evolution of CMOS sensor technology, driven by demand for compact, high-performance imaging systems under strict size and power constraints, has enabled significant advancements in digital microscopy. Short-wave infrared (SWIR) modular microscopes, exemplified by systems like the ToupTek SWIR microscope, now provide transformative capabilities for industrial and scientific applications by extending imaging beyond the traditional visible spectrum (400–700 nm) into the 900–1700 nm range.

SWIR modular microscopy bridges the gap between conventional optical systems and specialized IR imaging, offering unparalleled precision for next-generation material and electronic inspection.

The ToupTek SWIR Modular Microscope's key technological features:

- Optical Compatibility: SWIR microscopy leverages standard glass lens systems, avoiding the need for reflective optics required in mid-wave (MWIR) and long-wave infrared (LWIR) imaging. This compatibility allows seamless integration with conventional microscope platforms, reducing retrofitting costs.

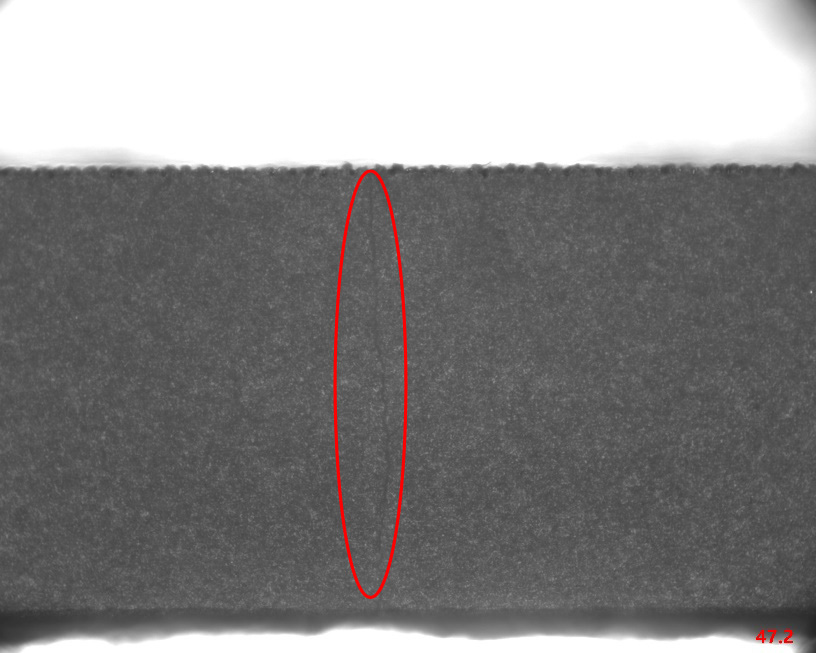

- Silicon Penetration Capability: SWIR photons, with energy below silicon’s bandgap (1.1 eV), enable non-destructive inspection of internal defects in silicon-based materials, such as microcracks in semiconductor wafers or soldering failures in electronic components.

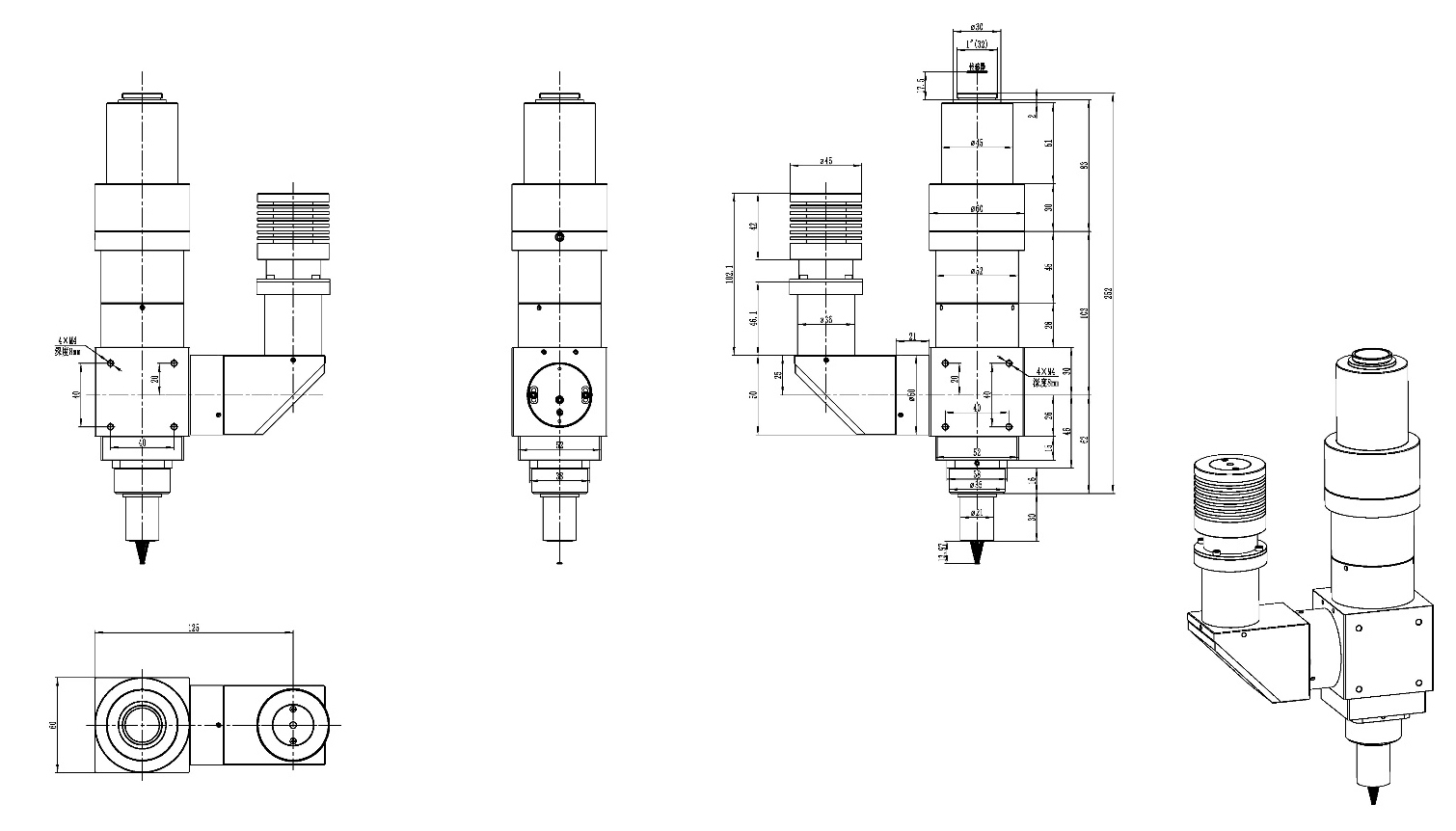

- Modular Architecture:

Illumination Module: Combine IR LEDs optimized for SWIR wavelengths, ensuring uniform sample illumination.

Imaging Module: High-sensitivity sensors and refined optical paths with large NA achieve micron-level resolution and small depth of field. With the Utilizes high-sensitivity InGaAs sensors (e.g., SWIR5000KM series camera) to achieve micron-level resolution. The camera’s compact design (80 × 80 × 45.5 mm³) and dual-gain mode enhance adaptability for high-speed (up to 5fps(USB3),93fps(CL),118fps(10G)) and low-noise imaging.

Mechanical Module: Features a precision CNC machining with anti-vibration design for stability in automated or high-throughput workflows.

Standard Working Distance Objective Parameters (45mm parfocal)

BSM-T180VA/BSM-T090VA:

BSM-T100VA: